Potato Slicer Machine,Ginger Slicer Machine,Fruit Slicer Machine,apple slicing machine Jiangyin Loongyi Machinery Co.,ltd , https://www.loongyi-asia.com

Magnetic Welding Clamps: The Ideal Solution for Secure and Easy Welding

Welding is the process of joining two metal pieces using heat, pressure, or a combination of both, resulting in a strong bond as the materials cool and solidify. However, keeping the workpieces securely in place during welding can be a major challenge, especially when dealing with complex shapes or difficult angles. This is where magnetic welding clamps come into play, offering a reliable and efficient solution.

Magnetic welding clamps are specially designed tools that use powerful magnets to hold metal parts firmly in position during the welding process. These clamps are particularly useful when working with irregular or curved surfaces, where traditional clamps may not provide sufficient grip.

In this article, we’ll take a closer look at how magnetic welding clamps function, their advantages, and why they’re becoming an essential tool for welders around the world.

### How Magnetic Welding Clamps Work

Magnetic welding clamps typically consist of a strong ferrite magnet combined with a sturdy clamp mechanism. Ferrite magnets are known for their high strength, heat resistance, and cost-effectiveness, making them ideal for industrial applications. The clamp holds the workpiece in place, while the magnet ensures it remains fixed against the metal surface.

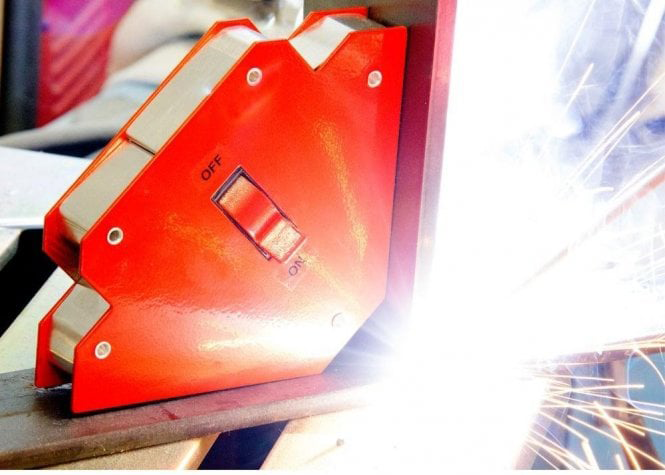

The magnetic field generated by the clamp provides a secure grip, allowing the welder to focus entirely on the welding task without worrying about movement or misalignment. Some models feature a mechanical switch that allows the magnet to be turned off, making it easier to reposition the workpiece before locking it in place again. This feature also makes cleaning the magnet more convenient, as any metal debris can be easily wiped away when the magnet is inactive.

### Benefits of Magnetic Welding Clamps

**Secure Hold**

One of the biggest advantages of magnetic welding clamps is their ability to hold workpieces firmly in place, even in challenging positions. They are especially effective for complex or awkwardly shaped materials where conventional clamps might fail.

**Easy to Use**

These clamps are simple to attach and adjust, making them suitable for a wide range of welding projects. Their quick setup and flexible positioning make them a favorite among professionals and hobbyists alike.

**No Marks or Damage**

Unlike traditional clamps that can leave dents or scratches, magnetic clamps hold the material without applying pressure, ensuring a clean and undamaged surface after welding.

**Highly Versatile**

Magnetic clamps can be used on various types of metal surfaces, including curved, flat, or irregular ones. They are compatible with multiple welding processes, such as MIG, TIG, and Stick welding, making them a valuable addition to any workshop.

### Safety Considerations

While magnetic welding clamps are generally safe to use, it's important to follow proper safety protocols. The strong magnetic field can attract loose metal objects like nails, screws, or tools, which could become dangerous projectiles if they come loose during welding.

Always wear appropriate personal protective equipment (PPE), including gloves and eye protection. Additionally, ensure the work area is free from any ferrous materials that could be attracted to the magnet. Keeping the workspace organized and controlled is key to a safe and efficient welding environment.