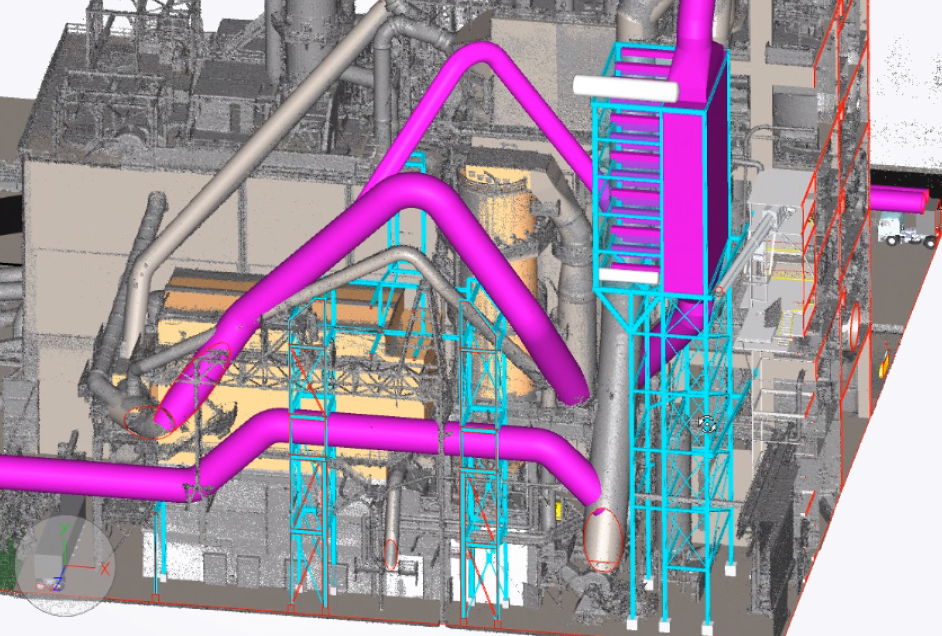

A cement plant in France recently used the Elios 3 drone for a scan-to-BIM project, capturing the entire site with its LiDAR scanner. This innovative approach transformed the way the facility is managed and planned, offering a new level of accuracy and efficiency. The Elios 3 captured every corner of the plant—both inside and outside assets—without leaving any gaps. Traditional terrestrial scans often miss areas due to obstacles or accessibility issues, but the Elios 3’s maneuverability ensures complete coverage. It's also easy to repeat the process, allowing for regular updates to the model as needed. Instead of taking 10 days with a traditional terrestrial laser scanner, the Elios 3 completed the scan in just one day. This massive time reduction not only accelerated the project timeline but also minimized operational disruptions. By using the Elios 3, the need for contractors to be on-site for an extended period was eliminated. A single day of flight replaced a week of scanning, reducing the impact on daily operations and improving workflow efficiency. The faster data collection and streamlined post-processing made the entire process more cost-effective. By handling the work internally, the plant avoided the high costs associated with hiring external contractors, further optimizing budget use. As digital transformation continues to reshape the construction and industrial sectors, more companies are turning to Scan to BIM to create accurate digital replicas of real-world environments. BIM (Building Information Modeling) is now the standard in architecture, engineering, and construction, enabling better planning, collaboration, and decision-making. With Scan to BIM, laser scans of physical sites can be converted into detailed 3D models, helping teams simulate construction processes, identify potential issues early, and ensure alignment between as-built and as-designed structures. This shift not only improves communication but also reduces errors, rework, and overall costs. Holcim, one of the world’s leading cement producers, has launched the "Plants of Tomorrow" initiative to integrate Industry 4.0 technologies across its operations. As part of this effort, the company is digitizing its production sites to improve efficiency, reduce carbon emissions, and enhance performance. One of the key components of this project is the creation of a digital twin—a virtual replica of the entire cement plant. This digital twin allows the plant to plan future upgrades, streamline communication with contractors, and track progress toward sustainability goals. The data collected from the scan will also help the site qualify for European grants by demonstrating its commitment to reducing environmental impact. The Elios 3 has already proven its value at this site for asset inspections and stockpile monitoring. Its pilots are well-trained and confident in the drone’s accuracy, which is why it was chosen for the BIM project. The challenge was to capture the complex internal layout of the plant, including tight spaces between pipes and ducts that are hard to access with traditional methods. Traditional scanning would have taken at least 10 days and cost around €30,000 in contractor fees. Plus, if initial scans were incomplete, additional site visits would be required, further delaying the project. In contrast, the Elios 3 allowed the team to collect all necessary data in just one day, with in-house processing cutting down the time even further. A point cloud showing the detailed environment captured by the Elios 3 The scan provided a comprehensive view of the plant, including areas that were previously difficult to reach. After just two days of post-processing, the team had a complete, high-quality .las file ready for use in their BIM software. Industrial sites like cement plants are full of complex structures, making it challenging to get a complete scan with traditional equipment. The Elios 3, however, can navigate tight spaces and avoid obstacles, ensuring no area is left unscanned. This capability was crucial for creating a fully accurate BIM model of the site. With the Elios 3, the team was able to gather all the necessary data in a single day, compared to weeks with a terrestrial laser scanner. This not only saved time but also reduced costs and improved data quality. The Elios 3 provides safe and accurate access to hard-to-reach areas Post-processing involved aligning multiple scans and removing low-quality data such as dust or out-of-range measurements. The final BIM model was ready within a week, giving the team a powerful tool for planning and design. The success of this project has had a significant impact on the plant. Not only did it save money and time, but it also ensured complete data coverage, eliminating the need for multiple scanning sessions. The in-house team’s familiarity with the site made the process smoother and more efficient than relying on external contractors. The plant aimed for a "schematic design" level of BIM (Level of Development 200), and the Elios 3’s LiDAR data met this requirement perfectly. This allowed the team to create a detailed model that supported engineering layouts and spatial planning for new installations. A schematic BIM model used for engineering layout and spatial planning Thanks to the accuracy of the BIM model, the plant can now plan where to install carbon capture technology and other green initiatives. This information can be shared with construction teams, ensuring precise placement of ducts, fans, filters, and heat exchangers. In addition, the BIM model serves as proof of the plant’s sustainability efforts, which could help secure funding from the EU and demonstrate compliance with environmental regulations. The use of the Elios 3 for this project represents a major step forward in bringing Industry 4.0 to the cement industry. The resulting BIM model has already been shared with subcontractors, proving its value and simplifying project coordination. The benefits of using the Elios 3 are clear: faster data collection, less disruption, and full coverage. Compared to traditional methods, the process is much more cost-effective, with only one day of scanning and a few days of post-processing needed instead of a week of fieldwork and longer data analysis. This project also sets the stage for future improvements. If the plant undergoes major changes, the existing BIM model can be updated quickly using the Elios 3, saving time and resources. Looking ahead, the team plans to use the drone’s LiDAR and ultrasonic sensors for ongoing asset digitization and remote inspections, ensuring both safety and efficiency. 2 Ton Wheel Loader,Compact Wheel Loader,High Dumping Loader,Compact Wheel Loader For Sale Shandong Yineng Heavy Industry Co.,Ltd , https://www.yinengloader.comDrone Scan to BIM: The Elios 3 Digitizes a Cement Plant

Key Benefits at a Glance

Full Data Coverage

Speed of Execution

Minimal Site Disruption

Cost Efficiency

BIM in the Cement Industry

Using the Elios 3 for Scan to BIM

Flying the Elios 3 for BIM Data Collection

Applying the Drone Scan-to-BIM Model

The Advantages of Using Drone Scan-to-BIM Models