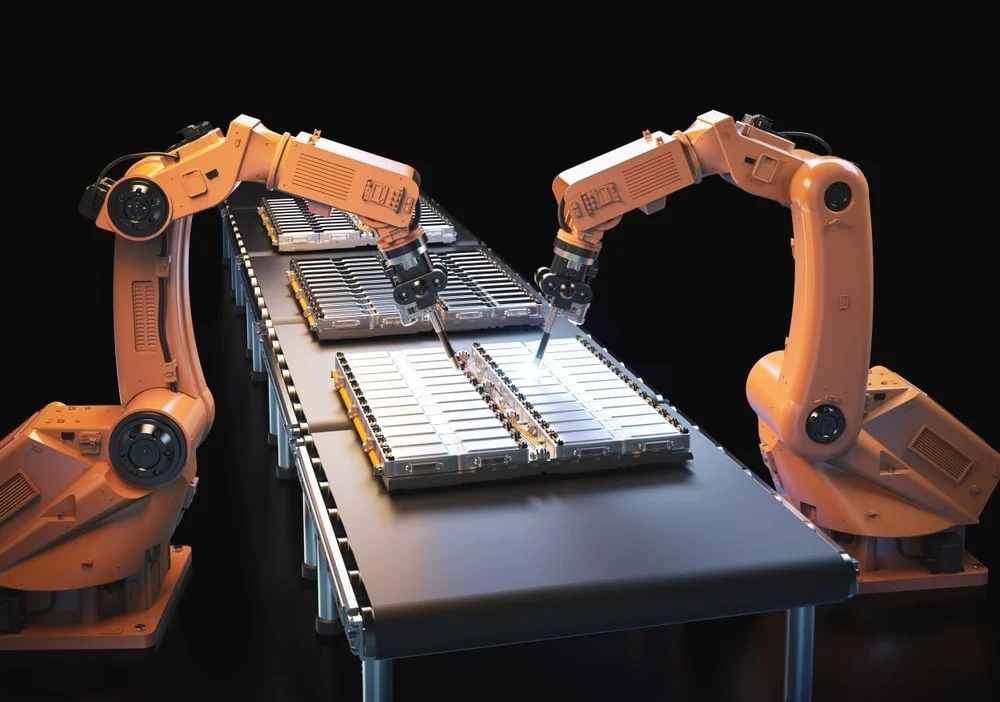

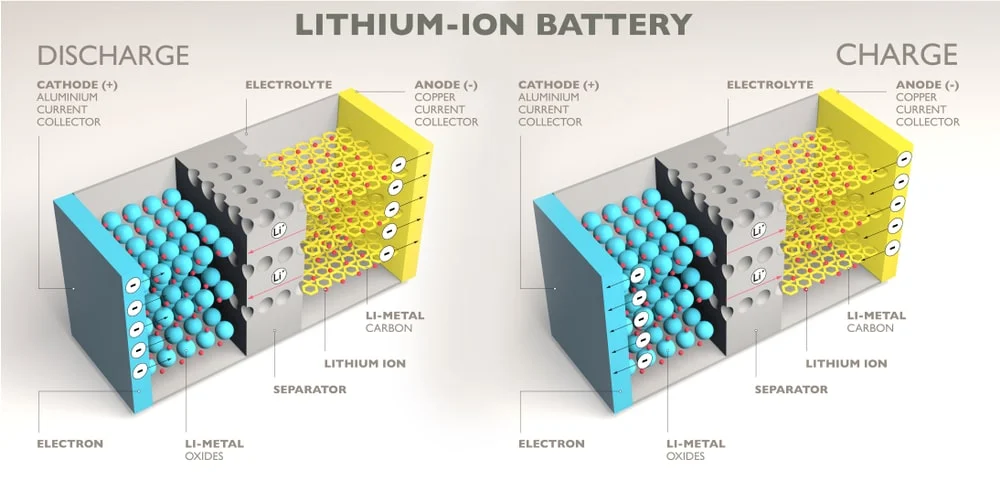

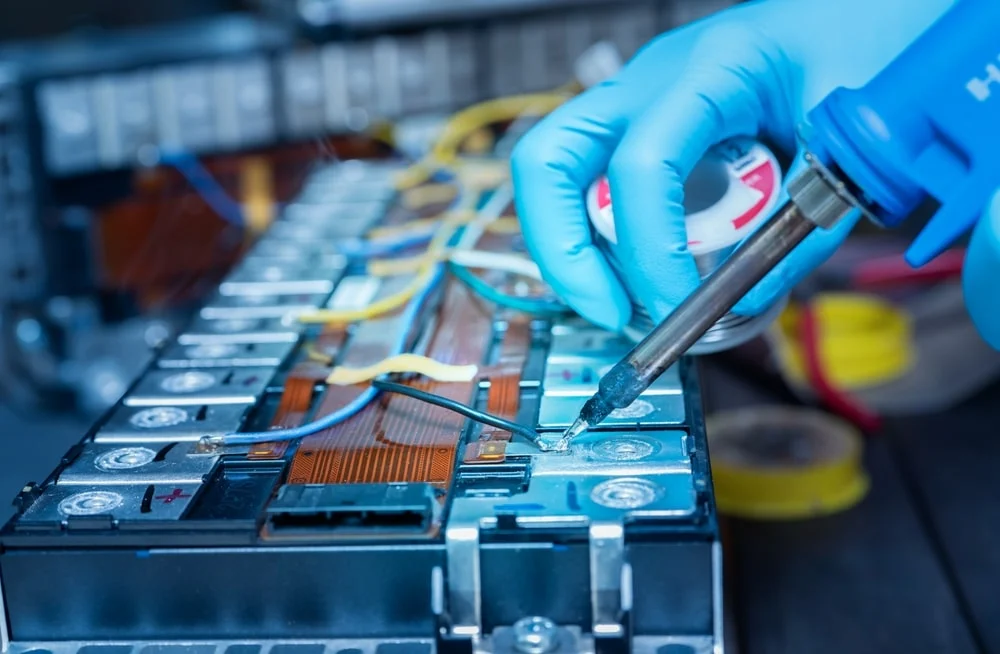

An electric vehicle (EV) battery is typically composed of thousands of rechargeable lithium-ion cells connected together to form the battery pack. Lithium-ion cells are the most popular choice due to their cost efficiency, offering a balanced mix of energy storage capacity and affordability. This makes them ideal for modern EVs that require both performance and value. With the rapid growth of electric mobility, demand for electric vehicles (EVs) and their batteries has surged dramatically. This raises important questions: How can battery manufacturers keep up with this growing demand? What materials are essential in producing an EV battery? In this article, we’ll take a closer look at the materials used in EV batteries, the manufacturing process, and the leading players in the industry. We'll also explore the challenges posed by supply and demand imbalances and what the future might hold for EV battery technology. EV batteries come in various shapes and sizes, depending on the design and chemistry of the cells. Before diving into the materials, it's important to understand the different types of cell structures used in EVs. These include cylindrical, prismatic, and pouch cells, each with its own advantages and limitations. There are three main types of battery cells used in electric vehicles: cylindrical, prismatic, and pouch cells. While coin cells exist, they are primarily used for research and not for commercial EV applications. Cylindrical cells are the most commonly used type, similar in shape to AA or AAA batteries. They are known for their durability and cost-effectiveness, making them a popular choice for many EV manufacturers. However, they may have limitations in terms of power output compared to other cell types. Prismatic cells are larger than cylindrical ones and offer better energy density and heat management. They are becoming more popular as EVs continue to evolve and require more efficient power solutions. Pouch cells are encased in a flexible plastic material, allowing for more efficient space usage. However, their delicate casing requires additional protection to prevent damage during use. Beyond their physical structure, EV batteries vary based on their chemical composition. The most common type is the lithium-ion battery, which uses lithium, nickel, cobalt, and manganese in the cathode, and graphite in the anode. Other chemistries like nickel-manganese-cobalt (NMC) and nickel-metal hydride (Ni-MH) were widely used in early EV models. Lead-acid batteries, while still used in some conventional vehicles, are not suitable for large-scale EV applications due to their low energy density. Lithium-ion batteries consist of multiple layers, including a cathode, anode, and electrolyte. The cathode is usually made from a mix of lithium, nickel, cobalt, and manganese, while the anode is typically composed of graphite. These cells are then enclosed in a protective casing, often made of aluminum or steel, to ensure safety and durability. In addition to the raw materials, an EV battery requires several key components to function properly. These include the battery module array, battery management system, electrical system, cooling system, and a protective case. This refers to the group of cells connected in modules to form the full battery pack. Each module contains a set number of cells wired together. The battery management system (BMS) ensures optimal performance by monitoring and regulating each cell’s charge level, managing temperature, and protecting against overcharging or overheating. This includes all wiring, fuses, and connections required to operate the battery efficiently and safely. Since EV batteries generate heat, a cooling system is essential to maintain safe operating temperatures and extend battery life. This provides a secure and durable housing for the entire battery pack, ensuring it is protected from environmental factors and mechanical stress. Due to the high costs and technical complexity involved, EV battery production is dominated by a few major companies. The top manufacturers include CATL, LG Energy Solution, and BYD, among others. CATL leads the market with a significant share, followed by LG Energy Solution and BYD. These companies play a crucial role in meeting the global demand for EV batteries and shaping the future of electric mobility. As EV adoption grows rapidly, so does the demand for critical raw materials such as lithium, cobalt, and graphite. This has led to supply chain challenges, including shortages and rising prices. Graphite, a key component in the anode, is currently facing shortages, which could further impact battery production and pricing. Despite these challenges, the future of EV batteries looks promising. Innovations in recycling, new battery chemistries, and advancements in energy efficiency are helping to address supply issues and reduce environmental impacts. Recycling initiatives are gaining traction, allowing for the recovery and reuse of valuable materials from old batteries. This not only helps reduce waste but also lowers the need for new raw material extraction. Looking ahead, continued investment in R&D, policy support, and sustainable practices will be key to ensuring that EV batteries remain affordable, efficient, and environmentally friendly. If you're interested in learning more about EV batteries, check out our articles on how much they cost or how they can be recycled.  Wooden Color Coated Steel Coil Wooden Color Coated Steel Coil,Wooden Color Coated Coil,Wooden Grain Steel Coil,Wooden Grain Aluminum Coil WENZHOU ICL INDUSTRIAL CO., LTD. , https://www.cniclsteel.com

The Rise of Electric Mobility and EV Battery Production

What Are EV Batteries Made Of?

The Different Types of EV Battery Cells

1. Cylindrical Cells

2. Prismatic Cells

3. Pouch Cells

What Materials Are Most Popular for EV Batteries?

What Are Lithium-Ion Batteries Made Of?

What Are the Components Needed for the Battery?

Battery Module Array

Battery Management System

Battery Electrical System

Battery Cooling System

Battery Protection Case

Who Manufactures Them?

Supply and Demand Gap

The Future of EV Batteries

What are electric car batteries made of?

An electric vehicle (EV) battery is typically composed of thousands of rechargeable lithium-ion cells connected together to form the battery pack. Lithium-ion cells are the most popular choice due to their cost efficiency, offering a balanced mix of energy storage capacity and affordability. This makes them ideal for modern EVs that require both performance and value. Wooden Color Coated Steel Coil Wooden Color Coated Steel Coil,Wooden Color Coated Coil,Wooden Grain Steel Coil,Wooden Grain Aluminum Coil WENZHOU ICL INDUSTRIAL CO., LTD. , https://www.cniclsteel.com