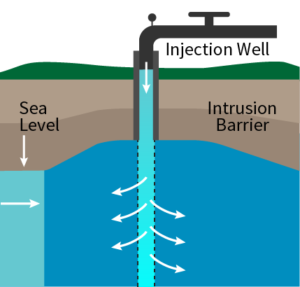

Unlocking the Potential of Groundwater Replenishment Systems in Southern California Water Infrastructure in Orange County Orange County, located in southern California, is a region that faces unique water challenges due to its semi-arid climate and rapidly growing population. With over 3 million residents and an expected increase of more than 300,000 people by 2035, the need for sustainable water solutions has never been more critical. The Orange County Water District (OCWD) has risen to this challenge with its innovative Groundwater Replenishment System (GWRS), which not only ensures a reliable water supply but also reduces dependence on imported water. Despite receiving less than one-third of California’s total precipitation, southern California is home to two-thirds of the state's population. This imbalance creates significant pressure on local water resources. While OCWD does import some water, this method is expensive and energy-intensive. Additionally, competition for water from other states and Mexico adds to the complexity of the situation. To address these issues, the district relies heavily on a large groundwater basin that produces nearly 300,000 acre-feet of water annually. However, since the 1940s, natural recharge has struggled to keep up with demand, leading to concerns about seawater intrusion into drinking water supplies. To combat this, OCWD launched the GWRS, a groundbreaking program that recycles wastewater into high-quality drinking water. This system helps protect the groundwater basin and reduces reliance on external sources, making it a cornerstone of the region’s water infrastructure. Water Infrastructure: The Five-Step Process Since its launch in 2008, the GWRS has become the largest advanced water recycling facility in the world, supplying up to 100 million gallons of potable water daily. It serves as a model for sustainable water management and highlights the potential of groundwater replenishment systems in arid regions. As climate change and population growth continue to shape the future, initiatives like the GWRS will play a crucial role in securing water resources for generations to come. Dry Desulfurization Denitration Crushing Equipment

1.Dry process desulphurization technology is using grinder and conveying fan combination of the grading system, to complete grinding powder spraying device, after smashing the sodium bicarbonate fine powder porous lamellar or shaped, structure, uniform particle size, fineness 200-6000 mesh is adjustable, with good dispersion, and then in solid superfine powder by high pressure centrifugal fan, direct injection into the furnace or in the reaction tower, It can effectively remove more than 95% of SO2 and HC in the tail gas, and the removal rate can reach 99%.

2.The equipment adopts the specialty of domestic and foreign dry mechanical crusher, according to the need to use large air volume into the cavity or water jacket cooling, in order to reduce the crushing heat, to prevent the shortcomings of material particles sticking to the wall, sticking to the crushing plate;

3.Crushing and grading machine, can reach the fineness requirements of the material in time to send out, avoid over-crushing, narrow distribution of material particle size, fineness 200-6000 mesh, online adjustable.

Dry Desulfurization Equipment,Baking Soda Grinder,Sodium Bicarbonate Grinding Machine,Baking Soda Crusher Shandong Jing Xin Powder Equipment Technology Co., Ltd. , https://www.jxpowder.com