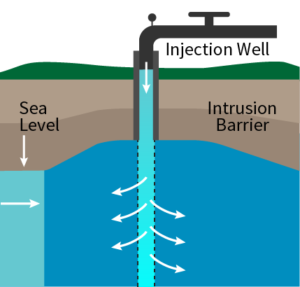

Exploring the Power of Groundwater Replenishment in Southern California Water Infrastructure in Orange County Orange County, located in southern California, is home to nearly 3 million residents and is expected to grow by more than 300,000 people by 2035. With water scarcity becoming an increasing concern, the Orange County Water District (OCWD) has taken a proactive approach through its Groundwater Replenishment System (GWRS). This system not only ensures a reliable water supply but also reduces dependence on imported water, making it a model for sustainable water management. Despite receiving less than one-third of California’s rainfall, southern California supports two-thirds of the state's population. While OCWD does import some water, this method is both expensive and energy-intensive. As climate conditions change and precipitation declines, competition for water resources intensifies, especially with neighboring states and Mexico. To address these challenges, OCWD relies heavily on a large groundwater basin that produces around 300,000 acre-feet of water annually. However, overuse in the 1940s led to concerns about seawater intrusion, prompting the need for a long-term solution. This is where the GWRS comes in. Launched as a key part of the region’s water strategy, the system helps maintain the integrity of the groundwater basin and minimizes reliance on external sources. It plays a crucial role in balancing supply and demand, ensuring a stable and safe water source for millions. The Five-Step Process of the GWRS Since its launch in 2008, the GWRS has become the largest advanced water recycling system in the world, supplying up to 100 million gallons of drinking water daily. Its success highlights the importance of innovation in water management, offering a sustainable model for other regions facing similar challenges. As water scarcity continues to rise globally, systems like the GWRS provide a promising path forward.

Universal crusher is suitable for pharmaceutical, chemical, metallurgy, food, construction and other industries. It can process hard and hard materials, including plastic, copper wire, Chinese herbal medicine, rubber, etc. It can also be used as the supporting equipment before the processing of micro crusher and ultra-micro crusher. Its powder collecting chamber adopts fully enclosed noise reduction structure, which can effectively reduce the working noise. The machine is equipped with a cooling device to reduce the temperature and work more smoothly. The motor speed of the machine is 5000 RPM. The machine is made of lcr18Ni9Ti stainless steel material, with strong wear and corrosion resistance characteristics, suitable for processing advanced and corrosive materials. The machine adopts the impact crushing method, so that the material into the crushing chamber, by the high-speed rotary six movable hammer impact, through the gear ring and the material collision with each other and crushed, crushed material with the help of air flow, through the sieve into the powder bag, leaving no residue. It has the advantages of high efficiency, low noise, reliable work performance and product quality, safe operation, drug hygiene and low loss.

1. Before using the universal jet mill, check whether all fasteners of the machine are tightened and whether the belt is tightened.

2. The running direction of the spindle must conform to the direction of the arrow shown on the protective cover, otherwise the machine will be damaged and personal injury may be caused.

3. Check whether the electric appliance of the mill is complete.

4. Check whether there are metal and other hard sundry objects in the crushing room of the mill, otherwise it will break the knife tool and affect the operation of the machine.

5. The purity of the material must be checked before crushing, and no hard metal sundry is allowed to mix in, so as not to damage the dao tool or cause combustion and other accidents.

The oil cup of the crusher should be frequently injected with lubricating oil to ensure the normal operation of the machine.

7. Stop feeding before shutdown, if not continue to use, to remove the machine left behind.

8. Regularly check whether the screen is damaged. If there is damage, it should be replaced immediately.

9. When using, if the crusher will have small vibration, be sure to tighten the handle connecting the cover to avoid accidents.

JXM Series Univeral Jet Mill,Universal Pulverizer,Universal Grinder,High Effective Jet Mill Shandong Jing Xin Powder Equipment Technology Co., Ltd. , https://www.jxpowder.com