An electric vehicle (EV) battery is typically composed of thousands of rechargeable lithium-ion cells connected together to form a battery pack. Lithium-ion cells are the most widely used due to their cost efficiency, offering the best balance between energy storage capacity and affordability. With the rapid growth of electric mobility, the demand for electric vehicles (EVs) and, consequently, EV batteries is increasing rapidly. This has sparked discussions about how manufacturers can meet this rising demand and what materials are required to produce these advanced power sources. In this article, we'll explore the materials commonly used in EV batteries, the manufacturing process, and the key players in the industry. We’ll also examine the growing supply-demand gap and its implications for the future of electric vehicles. EV batteries come in many different forms, from cell shapes to chemical compositions. Before diving into the materials used, it's important to understand the various types of physical cell structures. There are three main types of battery cells used in electric vehicles: cylindrical, prismatic, and pouch cells. Coin cells exist but are mainly used for research and not yet in commercial EV applications. Cylindrical cells are the most common type, similar in shape to household AA or AAA batteries. They are durable and easy to manufacture, but they may have lower power output compared to other types. Prismatic cells are larger and more efficient, with better heat management. Though less popular than cylindrical cells, they are gaining traction in the market. Pouch cells use flexible plastic casings, which make them space-efficient but require extra protection due to their fragile structure. EV batteries vary based on chemistry, meaning the materials used to store electricity differ. While lithium-ion (Li-ion) is the most common due to its low cost and high energy density, other chemistries like NMC and Ni-MH were used in early EVs. Lead-acid batteries, once common in traditional cars, are still used today but are not suitable for large EVs due to their low energy storage capacity. Lithium-ion batteries contain lithium, along with other elements such as nickel, cobalt, and manganese in the cathode, and graphite in the anode. These layers work together to store and release energy efficiently. The cells are enclosed in aluminum or steel casings that protect the battery and keep it intact. Beyond the raw materials, EV batteries rely on several key components to function effectively. Let’s take a closer look at each one. This refers to the group of cells that store power. These are combined into modules and then assembled into the final battery pack. The battery management system (BMS) ensures the battery operates safely and efficiently. It monitors each cell, regulates charge levels, and manages temperature to prevent overheating. This includes all the wiring, fuses, and connections that allow the battery to operate under high voltage conditions. EV batteries generate heat, so a cooling system is essential to maintain performance and safety. It uses coolant to dissipate heat away from the cells. The protection case ensures the battery is secure, waterproof, and resistant to shocks and vibrations. Due to the complexity and high costs involved, most EV battery production is concentrated in a few major companies. The leading manufacturer is CATL, holding around 34% of the global market share. China dominates the production of cathodes and anodes, and most raw materials for EV batteries also come from there. Next is LG Energy Solution, with 14% of the market. They recently partnered with Honda to build a new plant in the U.S., expected to start production around 2025. Third is BYD, a Chinese company with a 12% share. Unlike others, BYD is also an EV manufacturer, allowing it to control much of its own battery production. Other countries like the U.S., Japan, and South Korea also play a role, but China remains the dominant force in the EV battery market. Since 2020, the automotive sector has dealt with ongoing shortages of computer chips, impacting EV production. In addition, lithium and graphite shortages are becoming a concern, potentially increasing production costs. Graphite is a key component of the anode, and its shortage could lead to higher battery prices. This highlights the need for alternative solutions and sustainable practices. Despite current challenges, the future of EV batteries looks promising. One of the most exciting developments is EV battery recycling, which helps recover valuable materials and reduces environmental impact. Additionally, ongoing research is improving battery efficiency, reducing material usage, and making EVs more sustainable over time. While the manufacturing process is complex and resource-intensive, advancements in recycling, research, and policy support will help ensure EV batteries remain affordable and accessible in the years to come. If you're interested in learning more, check out our articles on how much EV batteries cost or how they can be recycled. Galvalume Steel Coil,Galvalume Steel,Galvalume Steel Sheet,Galvalume Zinc Steel Coils WENZHOU ICL INDUSTRIAL CO., LTD. , https://www.cniclsteel.com

The rise of electric mobility and EV battery production

What are EV batteries made of?

The different types of EV battery cells

1. Cylindrical cells

2. Prismatic cells

3. Pouch cells

What materials are most popular to use for EV batteries?

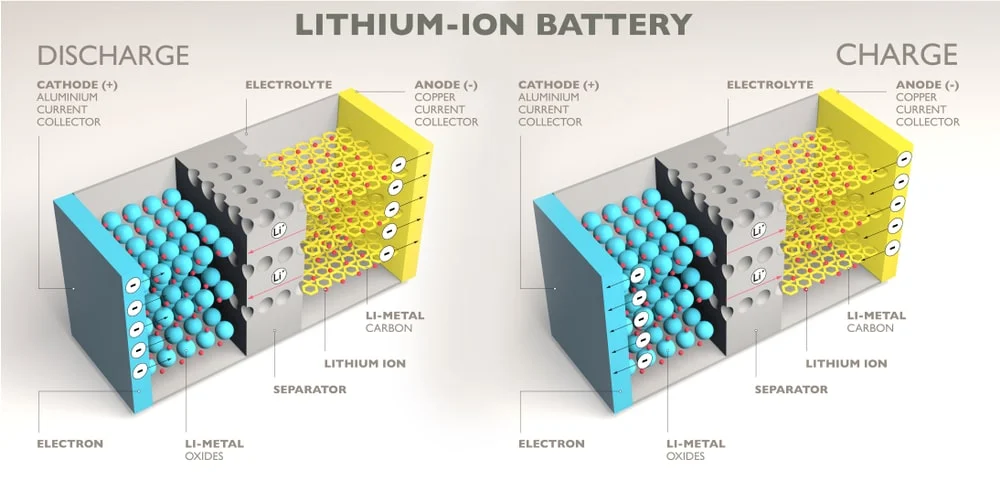

What are Lithium-ion batteries made of?

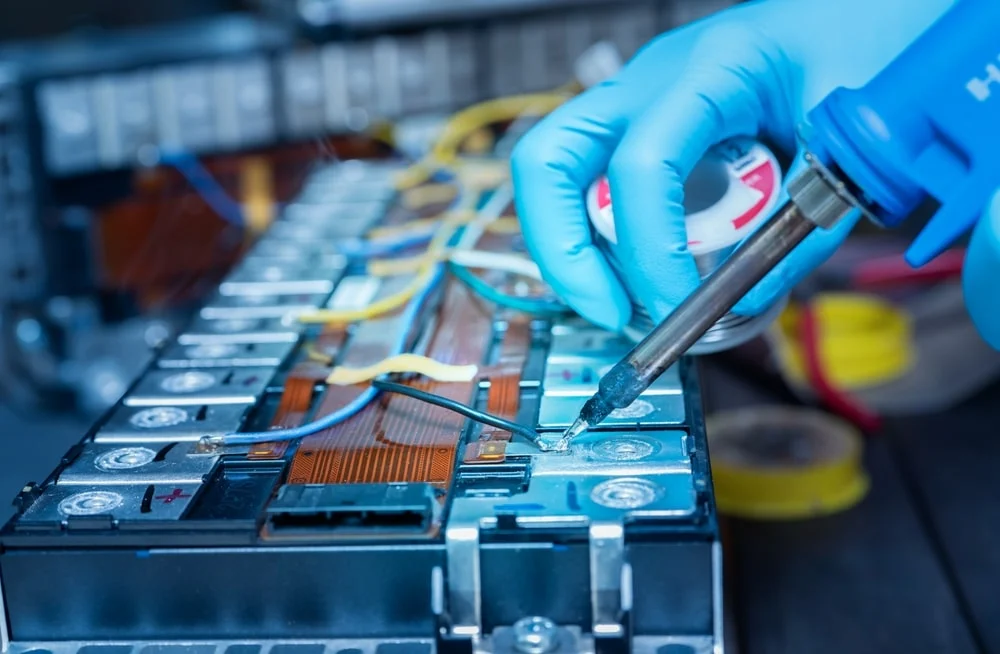

What are the components needed for the battery?

Battery Module Array

Battery Management System

Battery Electrical System

Battery Cooling System

Battery Protection Case

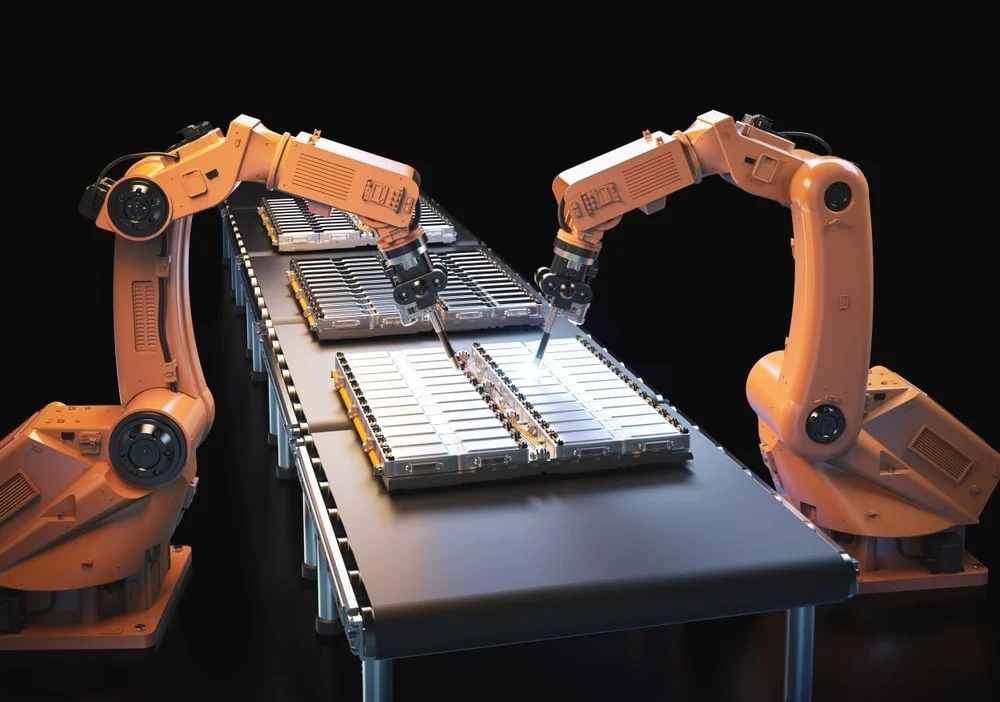

Who manufactures them?

Supply and demand gap

As electric mobility continues to grow, EV manufacturers face challenges in sourcing raw materials, especially for batteries.

The future of EV batteries

What are electric car batteries made of?

An electric vehicle (EV) battery is typically composed of thousands of rechargeable lithium-ion cells connected together to form a battery pack. Lithium-ion cells are the most widely used due to their cost efficiency, offering the best balance between energy storage capacity and affordability. Galvalume Steel Coil,Galvalume Steel,Galvalume Steel Sheet,Galvalume Zinc Steel Coils WENZHOU ICL INDUSTRIAL CO., LTD. , https://www.cniclsteel.com