Tungsten carbide turning Tools,inserts for turning,Tungsten Carbide Cnc Turning Tool,Turning Tools For Lathe,Carbide turning tools Zigong Brace Cemented Carbide Co.,Ltd , https://www.bracecarbide.com

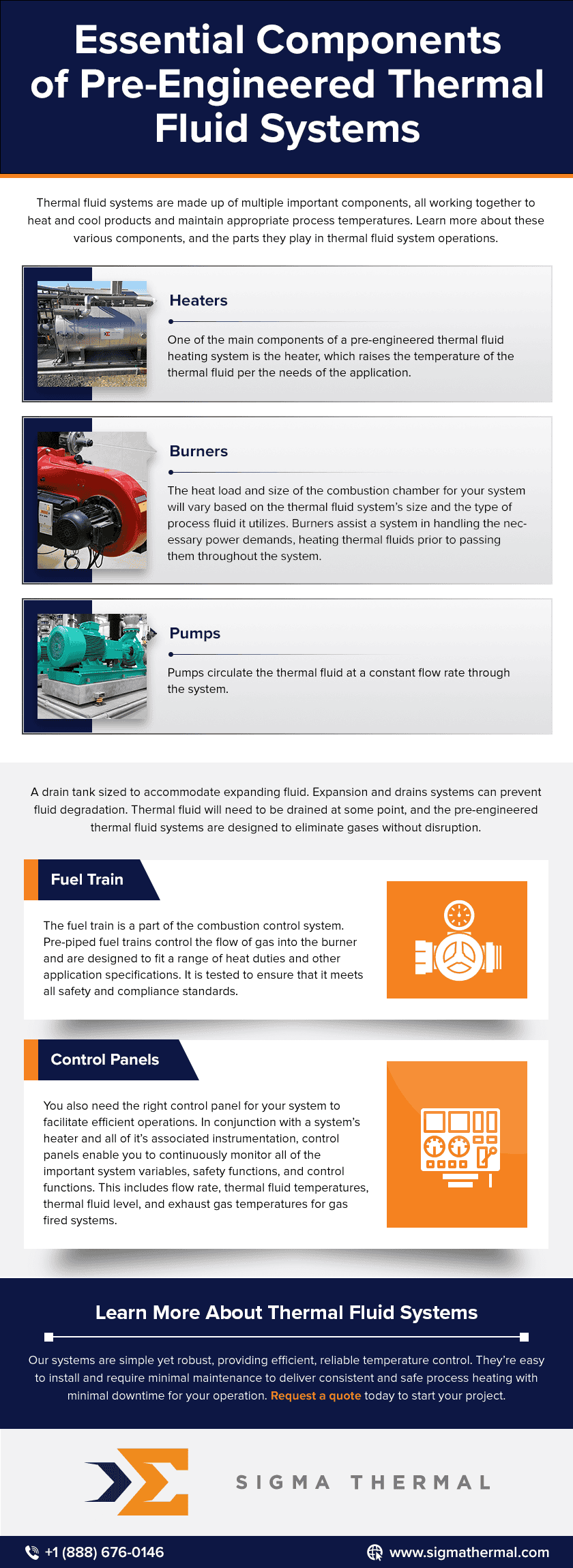

Essential Components of Pre-Engineered Thermal Fluid Systems

# Essential Components of Pre-Engineered Thermal Fluid Systems

Published by Sigma Thermal on March 11, 2024, at 7:04 AM | Leave a Comment

*Click to Expand*

---

Pre-engineered thermal fluid systems are closed-loop solutions designed to provide consistent heat for diverse industrial processes. By circulating thermal fluid continuously, they deliver effective and efficient heat transfer while maintaining precise temperature control. Unlike traditional steam boilers, these systems operate under low pressure even at high temperatures, offering flexibility across numerous industries. Whether you're working in food processing, plastics manufacturing, or pharmaceuticals, these systems can adapt to your unique requirements.

### Key Components of Thermal Fluid Systems

Thermal fluid systems rely on several critical components that work together to manage heat exchange and regulate temperatures. Here's a closer look at each essential part:

#### Heaters

Heaters are the heart of any thermal fluid system, responsible for raising the temperature of the thermal fluid according to the needs of the application. There are two primary types of heaters: electric and gas-fired. Electric heaters circulate thermal fluid around heating elements powered by electricity, avoiding reliance on fuels like oil or gas. Gas-fired heaters, on the other hand, burn natural gas or other combustible materials to generate heat. These heaters are available in both horizontal and vertical configurations, depending on space constraints and efficiency goals. Whether you opt for electric or gas-fired, heaters come in various sizes and power capacities to suit your specific requirements.

#### Burners

Burner selection depends heavily on the size of your system and the type of thermal fluid being used. Properly sized burners ensure the system can meet its heat load demands effectively. For instance, larger burners may be needed for industrial processes requiring higher temperatures or greater volumes of heated fluid. When acquiring a pre-engineered thermal fluid system, your provider should guide you toward the ideal burner configuration based on your project's specifications and operational needs.

#### Pumps

A dependable pump is crucial for maintaining steady thermal fluid circulation throughout the system. Pumps ensure the fluid moves at a consistent flow rate, enabling efficient heat transfer. While the flow rate through the heater remains constant, the flow to heat consumers can be adjusted via flow control valves. The return temperature to the heater fluctuates based on consumer demand, but the burner automatically adjusts to maintain a stable supply temperature.

When choosing a pump, consider the following:

- **Application-Specific Design**: Thermal fluid system pumps differ from standard hot water or boiler feed pumps. Options include magnetically coupled pumps, water-cooled pumps, air-cooled pumps with mechanical seals, or API-compliant models.

- **Material Selection**: Pump materials must match the thermal fluid and operating conditions. Alloy steel is often recommended for positive displacement pumps, whereas centrifugal pumps usually feature cast iron or ductile iron components.

- **Size Compatibility**: Ensure the selected pump aligns with your system's pressure loss potential and the thermal fluid's gravity at operational temperatures.

#### Expansion and Drain Tanks

Expansion tanks accommodate changes in fluid volume due to temperature fluctuations, preventing excessive pressure buildup within the system. Drain tanks collect spent or contaminated thermal fluid for disposal or recycling. Both tanks play vital roles in safeguarding system integrity and prolonging equipment lifespan.

#### Valves

High-quality valves are indispensable for controlling fluid flow and managing system pressure. At elevated temperatures, traditional valve seals may degrade quickly. Sigma Thermal recommends bellow-type seals for both manual and automated valves, especially when operating above 500°F. Although bellows seal globe valves are pricier than alternatives, their superior performance and reliability justify the investment, particularly in critical applications involving thermal oils.

#### Control Panels

An advanced control panel ensures seamless system management. Modern control systems integrate with heaters and instrumentation to monitor key parameters such as flow rate, thermal fluid temperatures, fluid levels, and exhaust gas temperatures (for gas-fired systems). Basic control setups suffice for straightforward operations, while programmable logic controllers (PLCs) offer enhanced functionality and integration capabilities with other plant systems.

---

### Why Choose Sigma Thermal?

Sigma Thermal specializes in delivering tailored industrial process heating solutions worldwide. Our pre-engineered and custom-built systems cater to diverse client needs, combining simplicity with robustness. With our expertise in design, engineering, servicing, and training, we empower businesses to optimize their thermal fluid operations. Expect minimal downtime, consistent performance, and reduced maintenance costs—all while achieving reliable temperature control.

Ready to elevate your thermal fluid system? Contact us today to request a quote and discuss how we can support your project!

---

**Have something to say?** Share your thoughts below!

*Note: Your email address will remain private.*

---

Leave a Comment (Cancel reply)