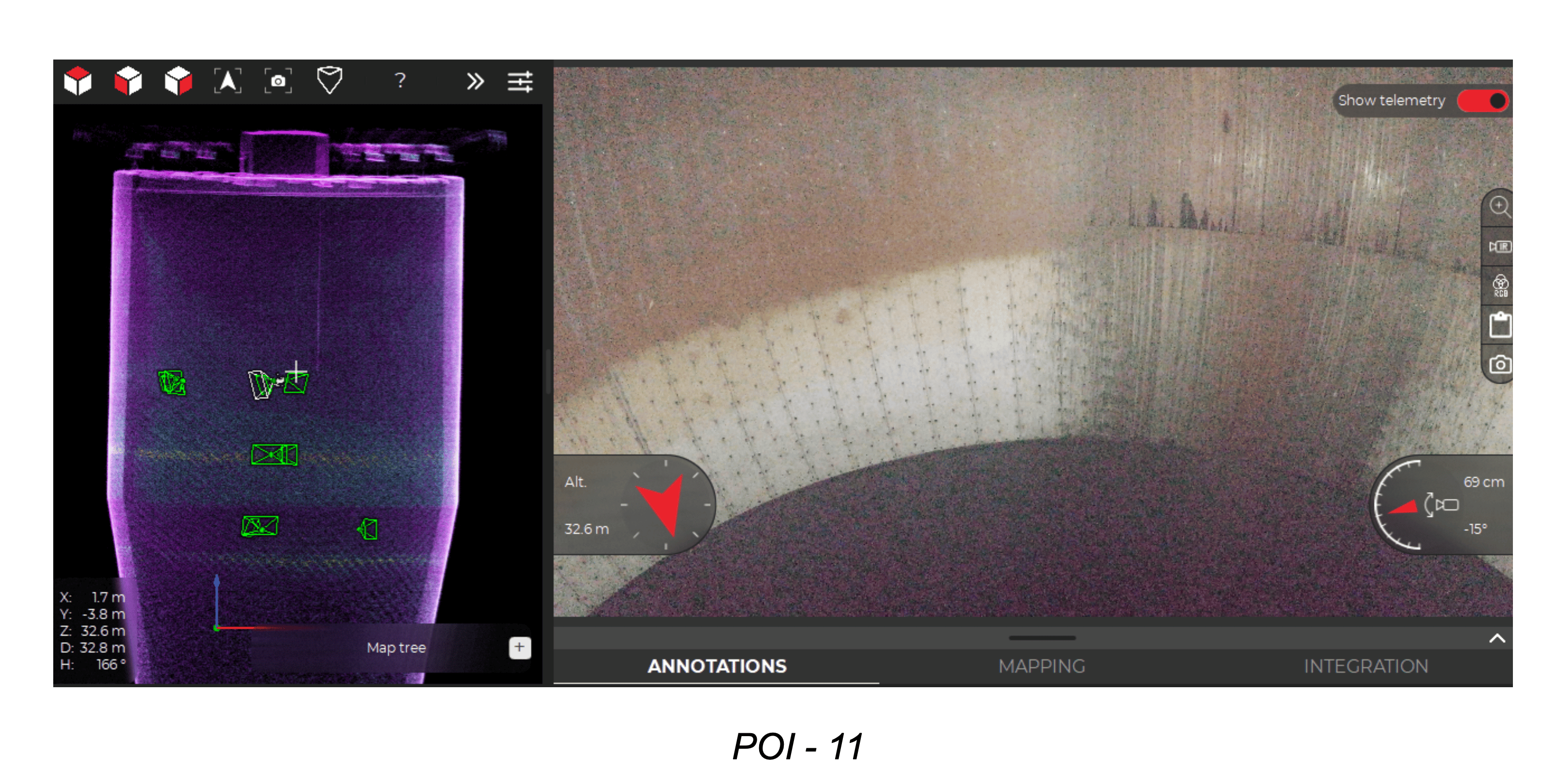

How can drones improve the safety and efficiency of inspecting storage bins? MIS Aero showcased the advantages of using the Elios 3 drone to a major mining client in Oman, demonstrating its capabilities effectively. Speed The Elios 3 enabled inspectors to complete the job in just four days instead of the usual 15, drastically reducing the time needed for the inspection process. Safety By eliminating the need for rope access and exposure to high dust levels, the Elios 3 ensured the safety of the inspection team while collecting essential data. Data Quality The MIS Aero team delivered full 3D models of the storage bin to their client, complete with points of interest. This made maintenance work easier and clearer.  Access Thanks to the Elios 3, the team could access multiple entry points and explore the entire interior of the storage bins, with no limits to the drone’s maneuverability. The pilot could fly confidently throughout the inspection.  Ensuring safety in mining inspections extends beyond just the caves and quarries—it also involves the equipment and materials used. Proper maintenance of critical equipment like storage bins and crushers is vital for improving both safety and operational efficiency in mining. However, managing and inspecting certain assets, such as storage bins, can pose significant challenges. Height and dust accumulation often limit access and visibility. A mining company aimed to enhance the safety of inspecting their storage bins to overcome these issues. A mining company in Oman wanted to conduct internal visual inspections of their storage bins to accurately detect defects or damage to the polyethylene (PE) lining inside the tanks. In the past, such inspections involved inspectors using rope access to enter the tanks and gather detailed data. This method carried substantial risks due to working at heights and the challenges posed by confined spaces and dust. The mine operator sought a safer and more efficient alternative, hoping to shorten the inspection period, which typically took 10 to 15 days. Finding a safer and more efficient inspection solution fell to the specialized service provider, MIS Aero. With extensive experience in offering both internal and external inspection tools, MIS Aero has recently integrated AI into its offerings. As the exclusive owner of the Elios 3 drone in Oman, obtained from the local Flyability partner SIGMA Enterprises, MIS Aero set a high benchmark for safe and efficient inspections. Focused on minimizing risks, MIS Aero was the ideal partner for the mine owner in this project. They planned to use the Elios 3 drone to inspect the interiors of the storage bins, eliminating the need for rope access and enabling faster data collection. Designed specifically for confined space inspections, the Elios 3 combines LiDAR and visual data collection simultaneously, making it the perfect mining drone capable of navigating challenging environments and the insides of assets like dusty storage bins safely. The MIS Aero team crafted custom flight plans to capture visual data around each storage bin. With seven bins, each standing 40 meters tall, they utilized multiple entry points and range extenders to ensure they could complete the data collection without personnel needing to enter the confined spaces. Additionally, MIS Aero coordinated with the local mining team to identify potential obstacles within the storage bins, ensuring the drone’s safety during flight. Following the flights, all data was processed using Inspector 4 to create a comprehensive report for the client. The client’s team reviewed the report to confirm it met the required level of detail—and it did! In the end, the client was particularly impressed by the geolocation of points of interest within the 3D point cloud. This feature made it easier to plan maintenance work by clearly identifying locations and specifics of required tasks. It also enhanced communication between engineers and maintenance teams, allowing everyone to visualize and plan work more effectively.  Setting a New Benchmark for Storage Bin Inspections The decision by the mine operator to embrace innovative technology, coupled with the expertise of MIS Aero’s team, resulted in a safer and significantly faster project. Eliminating unnecessary rope access and expediting the inspection process reduced client downtime and allowed for more efficient site operations. The storage bin LiDAR scan includes points of interest (POI) identified by inspectors during flight, and the client can compare the location of a POI in the laser scan with the photo taken by the Elios 3. The success of this project opened a new door for MIS Aero, showcasing the value of drones for inspections to a new client and paving the way for future collaborations. This project marked the first of its kind in Oman and represents an exciting step toward bringing more cutting-edge technology to the region. As we reflect on this project, it's clear that the integration of advanced technology in industrial inspections is not just about efficiency—it’s about redefining safety standards. The Elios 3 drone exemplifies how modern solutions can transform traditional practices, making them safer, faster, and more effective. For the mining industry, embracing such innovations is not just beneficial—it’s necessary for long-term success and sustainability. This collaboration between MIS Aero and the mining company demonstrates the power of partnership in driving progress. The ability to leverage technology like the Elios 3 to tackle complex challenges showcases the potential for future advancements in the field. As industries continue to evolve, adopting such technologies will be crucial for staying competitive and ensuring the highest levels of safety and productivity. Virgin PTFE,White Virgin PTFE,Colorful Virgin PTFE,Virgin PTFE Tube LIAONING HUARI NEW MATERIALS CO., LTD. , https://www.ptfebush.comInspection of a Storage Bin Using the Elios 3 at a Mine in Oman

Key Benefits at a Glance

What Does a Standard Storage Bin Inspection Look Like?

The storage bins, towering at 40 meters, present significant challenges for inspections without the use of additional access equipment.

The storage bins, towering at 40 meters, present significant challenges for inspections without the use of additional access equipment.Drone Inspections of Storage Bins with the Elios 3

The Elios 3 returning to the inspectors.

The Elios 3 returning to the inspectors.Planning Flights Inside Storage Bins

The Elios 3 pilot and an inspector search for points of interest during the flight.

The Elios 3 pilot and an inspector search for points of interest during the flight.