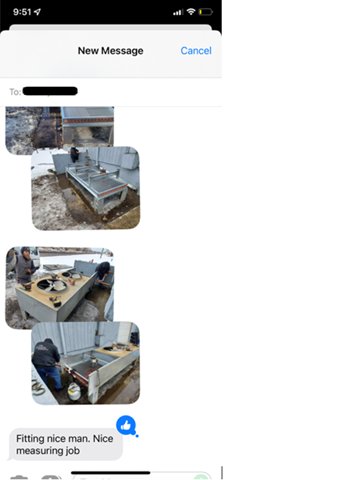

Join Chris Wright, a Chicago-area Account Manager, as he heads out to P&W Foundry for a high-pressure coil replacement job. Recently, we were called to an urgent job at P&W Foundry in Plano, IL, to install a replacement coil for a Liebert® condensing unit. The unit was critical for a production floor that manufactured time-sensitive parts for the U.S. Navy. With the unit down, the whole operation would come to a standstill, so we made it a priority to measure and build the coil on the same day we received the call. Since the paired equipment wasn’t being replaced, we had to ensure a perfect match in terms of coil circuitry, fins per inch, and piping connections to guarantee a direct replacement in performance. The coil was large but easily accessible, making the sizing process straightforward. The coil had several non-standard features, but nothing we hadn't seen before in the field. The copper connections extended from the bottom of the headers, which meant we had to replicate the exact placement for an easy field changeout. The flanges were also built non-standard, requiring additional bends on each of the entering air-side plate flanges to give the slab coil more stability on the four pillars it rested on. With detailed sketches and notes, we customized everything precisely. The customer placed the coil on a 5-day production cycle and was thrilled with the ease of installation! By the end of the week, they were fully back up and running, and the new coil performed flawlessly.

Our FZ Filter Pleated Bag Cages are the most common design, which include the Pleated Double wires cages, Pleated Single wires cages. The bag cages material are including the Carbon steel with high resistant painting, Pre-galvanized Bag Cages, AISI 304, AISI 316, Carbon steel with Cataphoresis treatment. This cage with dust filter bags, can enlarge the filter area of filter bags.

Pleated Bag Cages,Pleated Double Wires Cages,Pleated Single Wires Cages Shanghai Feizuo Environment Technology Co,.Ltd , https://www.fzfilter.comSite Bite: Replacing the Coil in a Liebert® Condensing Unit

Written by: Chris Wright

Nationwide Coils Account Manager, Chicago